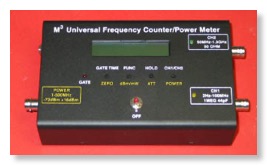

M3 Universal Freqency Counter / Power Meter

M3 Electronix FPM1 Power Meter / Frequency Counter

I noticed this kit before the first of the year on the net, and was really interested in it. I had previously built the M3 Semiconductor kit, and have been very happy with it. It has turned out to be a valuable addition to my bench. I finally decided I could not do with out this any more and needed to order one.

I ordered it on a Wednesday morning. Within an hour I received an e-mail from Mike at M3 stating that my order was received and it would ship out later that afternoon. I also ordered the matching RF standard. Mike stated that they where still on his work bench for burn in and testing, but would ship the following day.

The kit for the FPM-1 arrived in the mail on Friday. I spent Friday evening reading the documentation and inventorying the parts. I spent Saturday morning assembling the kit. Total build time was about 4-5 Hours, I did not keep track of the time closely.

Construction:

I will include some notes and comments on the construction of the meter. I deviated from the instructions in some places. I have also added comments of things I would have done differently if I was to do it again.

The inventory of the parts showed 1 extra 1K 5% resistor, and and 2 100K 1% resistors, but no 10K 1% resistor. I double checked them with a meter to confirm that I was reading the colors correctly. The Errata Sheet (Dated 8 Dec 2005) showed that step 13 was a 10K 1% [Brown-Black-Black-Red] resistor. [Brown-Black-Black-Red] is also listed as the Color code for a 100K 1% resistor in step 5. The schematic shows a 10K resistor for R12 so I am going to assume that it should be a 10K resistor. I fired of an e-mail to M3 and they confirmed that R12 should be a 10K 1% resistor. They also sent me an updated Errata Sheet Dated 5 - Feb - 2006. That shows the proper values and color codes for R12 and R21.

That leaves me with not having a 10K 1% resistor. I checked the parts cabinet here, and no 10K 1% where to be found. I went through a bunch of 10K 5% resistors to find one that was close. I can change it back out later when I get the correct part.

There are some errors on the circuit board, and a few in the manual. They are all well documented in the Updated Errata Sheet, and all are very minor. All the circuit board errors are errors on the silk screen, no traces have to be modified in any way.

Step By Step Assembly:

I followed these steps in order, with the exception that I chose to install all the 1% resistors first. I double checked all these with a meter before installing.

25) U4 7805 Regulator. See photo on page 4. Most of the body of the regulator is off the board, not just the metal tab.

38) AJ4 Pay special attention to this. I bent the center pin to make it fit on the board, but the screw hole on the keypad board did not line up with the pot. Bend the leads on the pot so that the body of the pot line up with the outline on the board closest to C5. The photo below shows AJ4 incorrectly installed. If you install it incorrectly like I did the leads will be too short to move the the pot later, and you will have to file out the hole in the switch board like I did.

Note Pot Not aligned with silkscreen

When I was done I had the following parts left over:

1K 5% Resistor ( Was over in inventory)

52.3 1% Resistor

100 5% Resistor

1 10uF Electrolytic (Used Later)

1 .1 axial lead Electrolytic. (Used Later)

Stacking and aligning the two circuit boards:

M) These wires will later be soldered to the power switch

K) Make sure that you can reach AJ4 through the hole in the switch board. Because I mounted AJ4 incorrectly I had to file the hole slightly.

Hole Filed to allow adjustment of AJ4

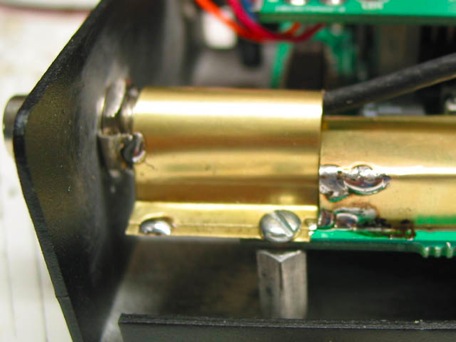

Putting It All Together:

6. 4.5 Inches makes this tight, cut it to 5 inches

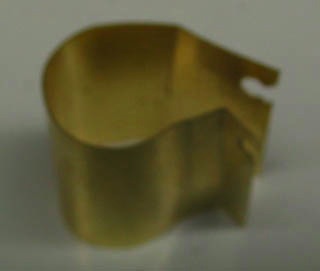

12. I made my final shield a little differently here. This design makes soldering a little bit easier.

I would recommend that you skip the shielding in steps 12-13 for now, and jump to the Let’s Make It Work Section. I had short caused by the shield touching C26 and I could not get the Power Meter calibration to work. I had to remove all the shielding to get to the board.

Once you have steps 1-5 in the calibration section done you can go back and install the shielding. You will have to do the calibration steps again after all the shielding is in place.

Final Shield In place

M3 Elextronix RF Calibrator:

I purchased the calibrator along with my kit. It can be used for many more things around the shop after using it to calibrate the kit. It comes fully assembled, Ready to use. It also makes calibrating the kit very quick and easy.

Push Button Problems:

I had problems with clearance on my Gate Time button. When the case was put on it would stick. I loosened all the screws and tried to slide the boards to one side as far as they would go. I even took the switch board off and tried to move the Gate Time button by re-soldering it. I still had the binding problems. The tolerances here are very close. I did not want to drill out the holes like the manual suggested, and take a chance of messing up the nice paint on the case. After looking at the problem a bit more, I decided that the whole circuit board assembley needed to be move left about 1/32 of and inch.

Solution:

Remove the tapered screws holding the stand offs to the bottom of the case. There is plenty of clearance in the holes for adjustment, but the taper part of the screw do not allow for any adjustment. By replacing these with standard flat screw you will be able to move the complete circuit board assembly around to allow the buttons to be centered in their holes.

Note: You might need to unsolder the shield from the power input BNC connector to allow the board to move.

Flat Head Screws

Conclusion:

The M3 Power/Frequency Counter is everything it is advertised to be. There are a few errors in the silkscreen on the board, and some changes on the schematic, but they are all documented in the errata sheeet. The folks at M3 are top notch and the kit went together rather smoothly. I will be using this kit for a long time to come.

73’s de KB9JJA / Dale

M3 Electronix Web Site